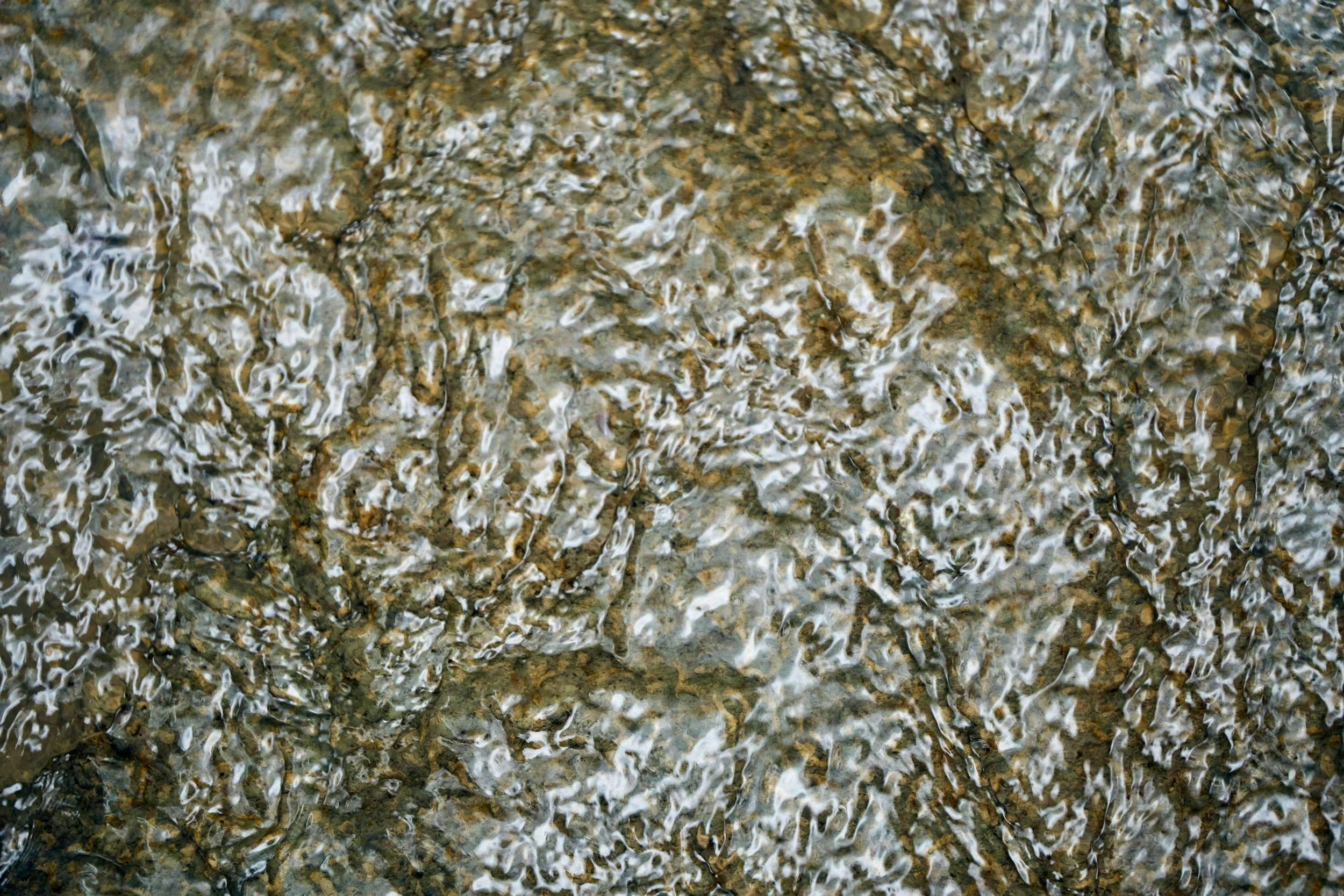

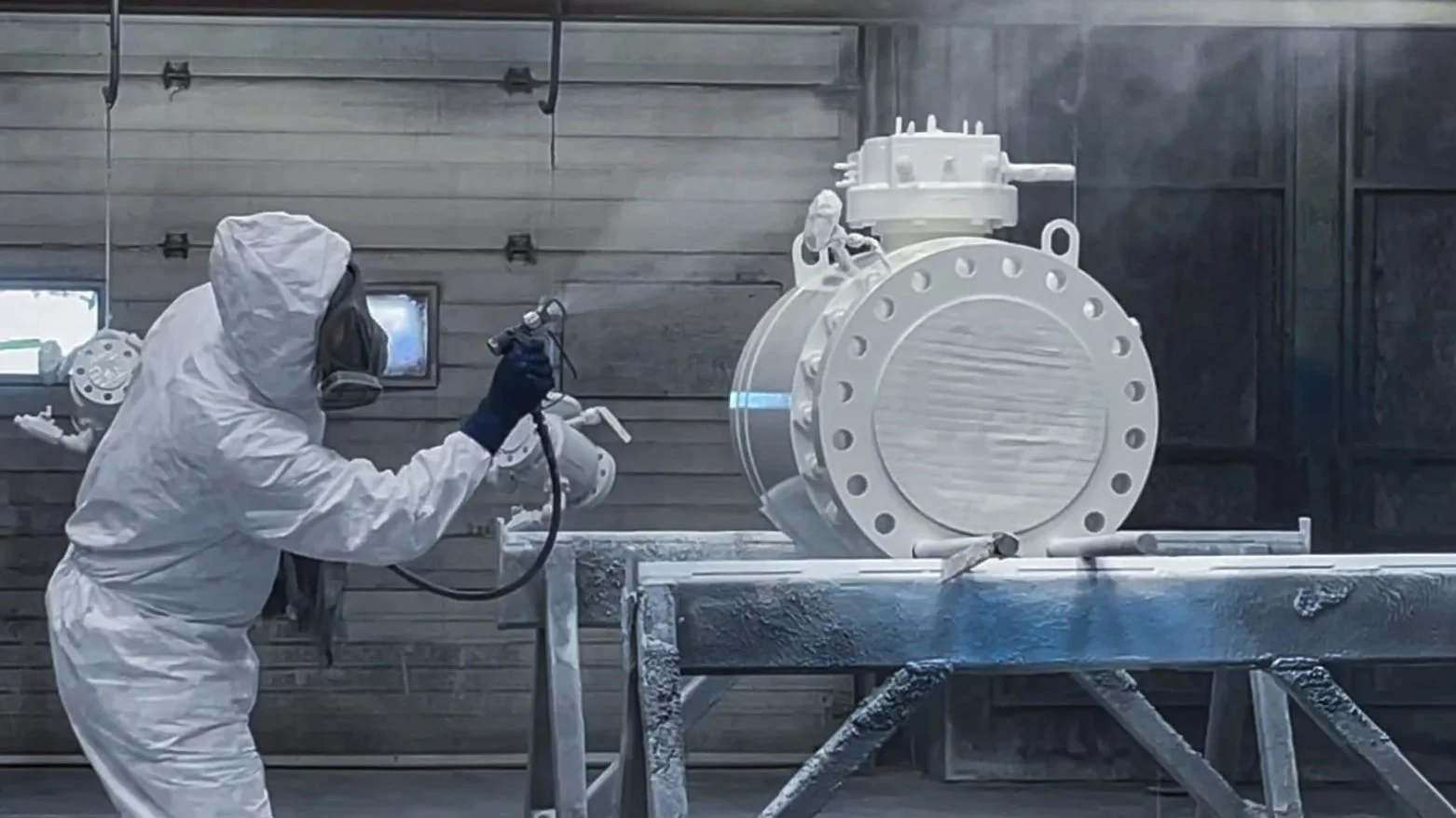

Sandblasting & Protective Coating Services in Alberta

With over 35 years of experience and more than 6.3 million custom-coated oil tools delivered worldwide, we’ve been the leading choice for protective coating for prominent companies across oil & gas, manufacturing, utilities, and construction.

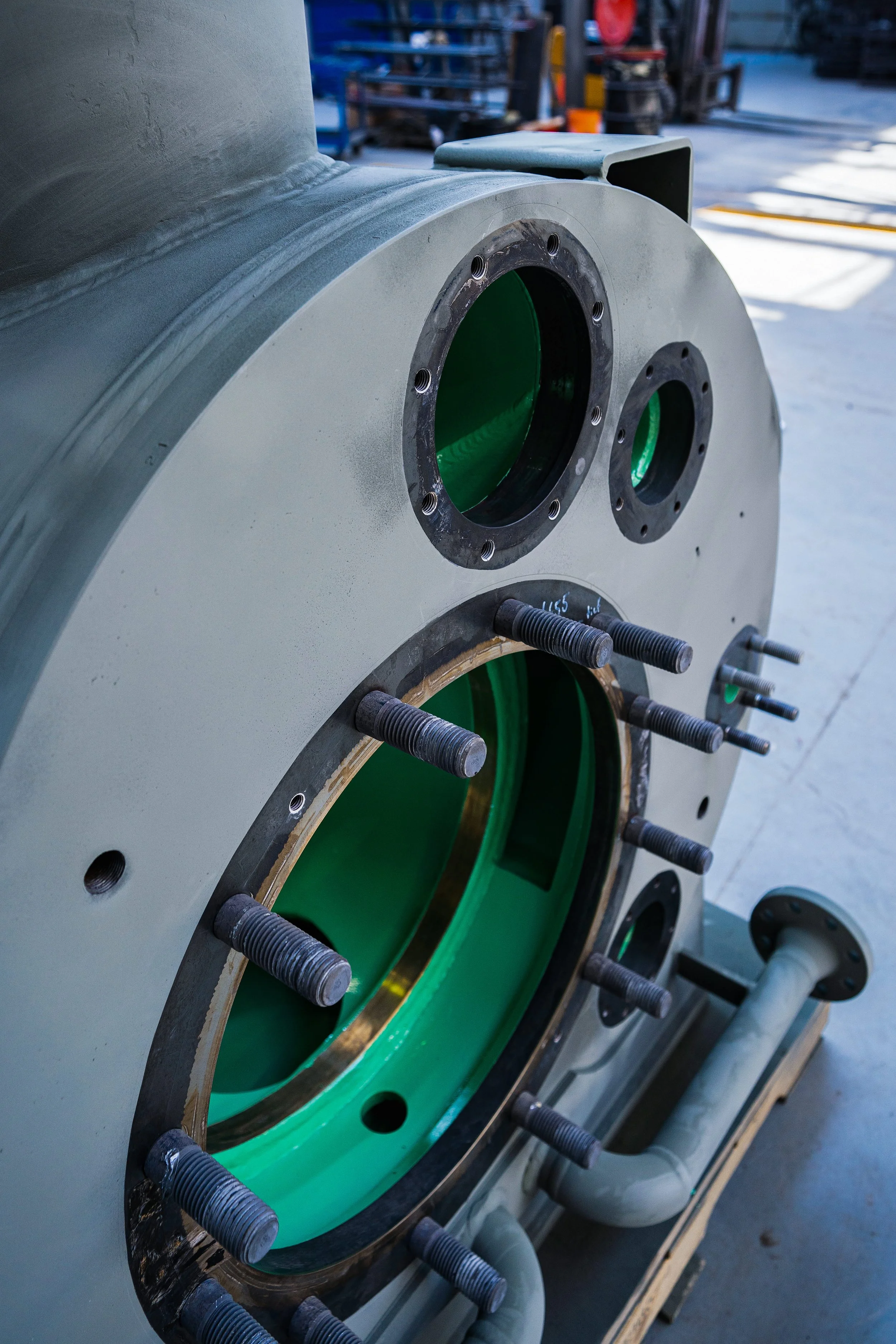

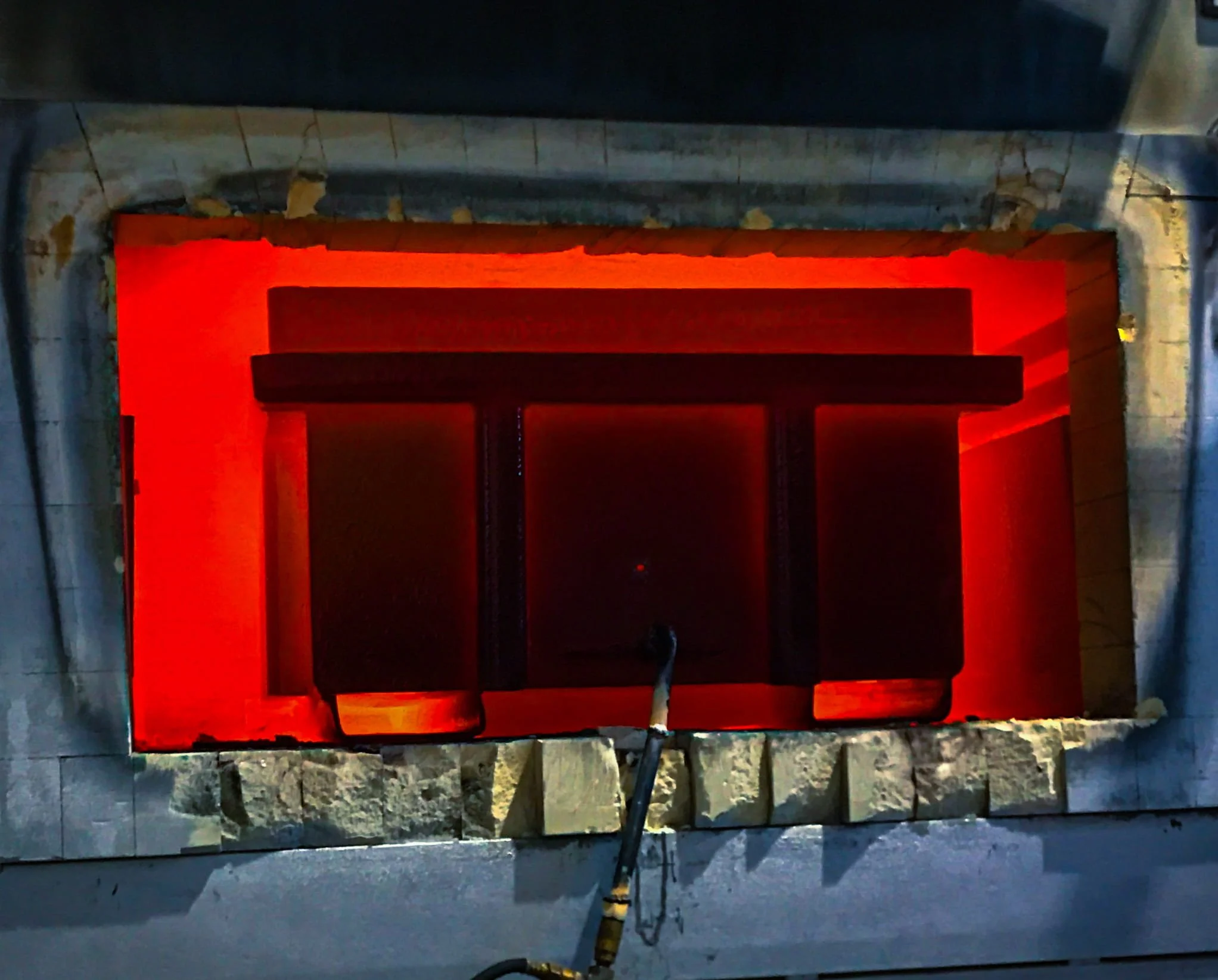

For over 35 years, Custom Coatings International has been a trusted partner to companies worldwide, protecting critical parts and components from abrasion, corrosion, and erosion. We specialize in sandblasting and protective coating services, using best-in-class vendors and holding every project to the highest quality standards. As an ISO-certified company, ISN member contractor, COR-certified workplace safety member, Bortec® (boronizing)-certified facility, and NACE Level 2–certified holder (on staff, with NACE Level 3 contact as needed), we are committed to quality and safety on every project. Our expertise has earned the trust of some of the largest oil and gas companies for their most demanding projects. Explore our full range of services and learn how we can help you extend the life and performance of your equipment.

Your Partner in Sandblasting and Protective Coating Solutions

Our Services

Click on the service below to learn more

Industries We Serve

At Custom Coatings International Inc., our surface preparation and protective coating solutions are trusted across a wide range of industries. From heavy-duty corrosion protection to precision-engineered finishes, we deliver long-lasting performance where it matters most

Oil & Gas

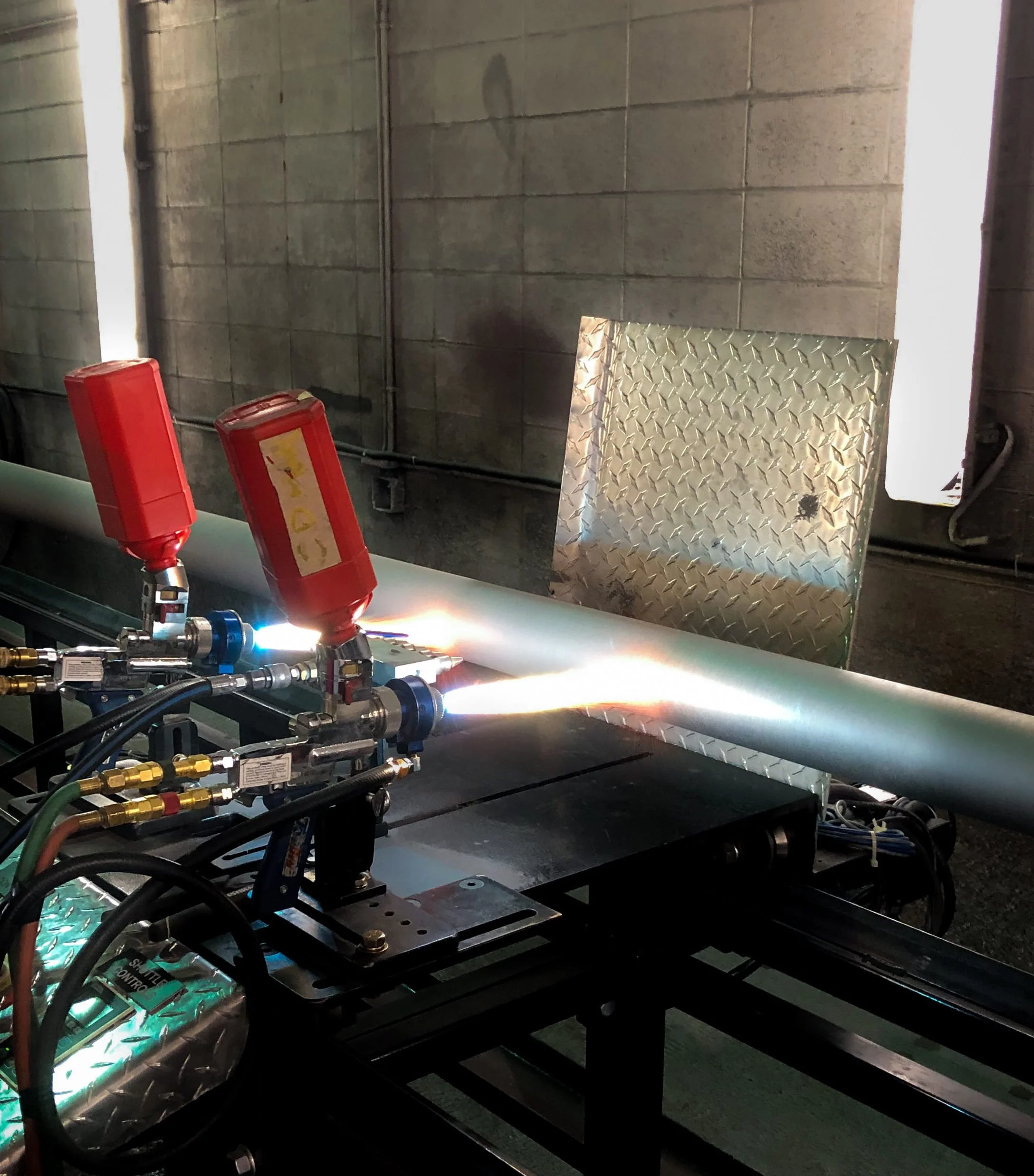

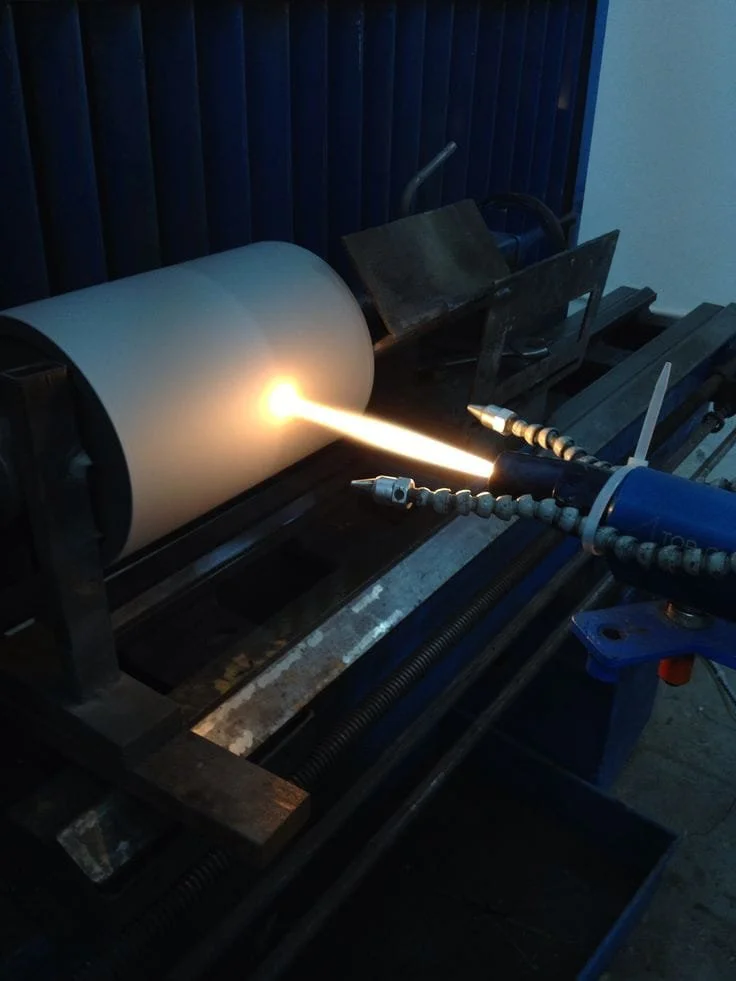

The oil and gas industry demands maximum durability in the harshest environments. Our blasting and coating services protect pipelines, wellheads, valves, drilling equipment, and processing facilities from corrosion, abrasion, and chemical attack, ensuring reliability in both upstream and downstream operations.

Construction & Infrastructure

From bridges and structural steel to tanks, piping, and heavy machinery, our coatings extend service life and protect against weathering, stress, and impact damage. Thermal sprayed aluminum, industrial coatings, and powder coating systems provide superior resistance to corrosion and environmental exposure in critical infrastructure projects.

Automotive & Transportation

Durability and aesthetics are equally important in transportation. Powder coating, zinc phosphate pretreatments, and polymer coatings are widely used on fasteners, frames, wheels, brake components, and protective housings. These finishes improve wear resistance, reduce corrosion, and enhance appearance for automotive, rail, and heavy trucking applications.

Aerospace & Defense

Aircraft and defense components face extreme conditions where precision and protection are critical. HVOF coatings, polymer/Teflon finishes, and thermal spray solutions safeguard landing gear, turbine parts, actuators, and weapon system components from wear, galling, and corrosion—while reducing downtime and maintenance costs.

Manufacturing & Industrial Equipment

From pumps and valves to gearboxes, rollers, and food grade machinery, our coatings provide superior protection against abrasion, chemical exposure, and heat. Zinc phosphate and polymer coatings enhance cleanability and performance, while dry film lubricants and HVOF systems extend component life in demanding manufacturing environments.

Custom Coatings International Inc. takes a consultative approach with all clients and projects, and provides the very best solutions to prolong the lifespan of our client’s equipment and components.

Why Choose Custom Coating International

Custom Tailored Solutions

We provide a broad range of custom solutions to meet our customer’s unique needs.

35+ Years of Coating Experience

Applied expertise & proven professionalism has allowed us to best serve our customers.

We employ 2 NACE Level 2 Coating Inspectors and provide staff on-going training for continuous improvement.

Committed to the Highest Quality

We always charge our best price and turn around time to every customer

No Hidden Fees

We provide the best in class turnaround times. We can accommodate for your time schedules.

Quick Turn Around Times on Orders

Request a Quote

To initiate the quoting process, please provide the following information (if available):

• Drawings or isometrics

• Coating specifications

• Operating environment details (temperature range and chemical exposure)

• Project timeline or required completion date

We look forward to working with you on finding the right protective coating for your project. If you have any questions, please contact us using the links below.

FAQs

-

At the time, Custom Coatings International does not conduct fieldwork. We do all our work in the shop, and ship and receive parts from across Alberta, Canada, and internationally.

-

Yes, Custom Coatings International can provide IPC System coatings. You can expect the same performance and quality through our “Teflon” Polymer coatings.

-

Our lead times vary by project type and quantity. We usually aim for a lead time of 4-7 business days for small jobs, 7-10 business days for medium-sized jobs, and 10-14+ business days for large jobs. We accommodate rush jobs if needed.

-

Yes, Pump Guard is the trademarked “Teflon” coating owned by CCI. Pump Guard Coatings have been the coating of choice for millions of components and parts.